Plasma and Oxyfuel Metal Cutting

Plasma and Oxyfuel Metal Cutting. Best in Class.

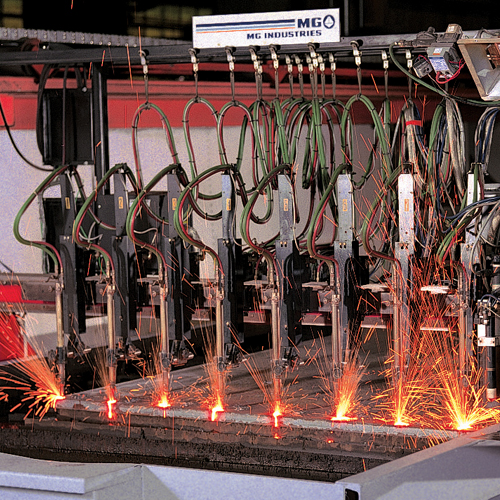

Our advanced line-up of CNC-controlled burn centers will efficiently accommodate your processing needs. Our large fleet of Oxyfuel and Plasma cutting equipment processes a wide range of material thicknesses, up to 6" thick. Our machines are networked via fiber optics to our server for instant access to computer-generated nesting programs. These advantages, combined with our trained inside processing technicians, ensure swift turnarounds, completed to your exacting standards.

Plasma and Oxyfuel Equipment

Port City Metal Services has CNC MULTI-TORCH OXYFUEL / PLASMA MACHINES with bed sizes up to 10’ x 120’. All machines are equipped with multiple oxyfuel torches with at least one plasma torch. Our fleet of CNC burn tables includes a MG Infinity Rotator bevel head and multiple 400 amp and 800 amp plasma units.

MODEL TORCHES TABLE SIZE

2018 MG MPC2000 1- Oxyfuel, 1 Plasma (400 Amp) w/ Bevel Head 12' x 90'

2015 MG MPC2014 4 - Oxyfuel, 1 Plasma (400 Amp) w/ Bevel Head 12' X 64'

2015 MG MPC2014 6 - Oxyfuel, 1 Plasma (400 Amp) 12' X 64'

2014 MG MPC2000 6 - Oxyfuel, 1 Plasma (400 Amp) 10.75' x 71.5'

2013 MG MPC2012 6 - Oxyfuel, 1 Plasma (800 Amp) 10.75' x 41.8'

2013 MG MPC2012 6 - Oxyfuel, 1 Plasma (400 Amp) 10.75' x 41.8'

2007 Alltra PG30-12 6 - Oxyfuel 13.6' x 53'

2006 Alltra PG30-10 2 - Plasma (130 & 260 Amp) 11.6' x 129'

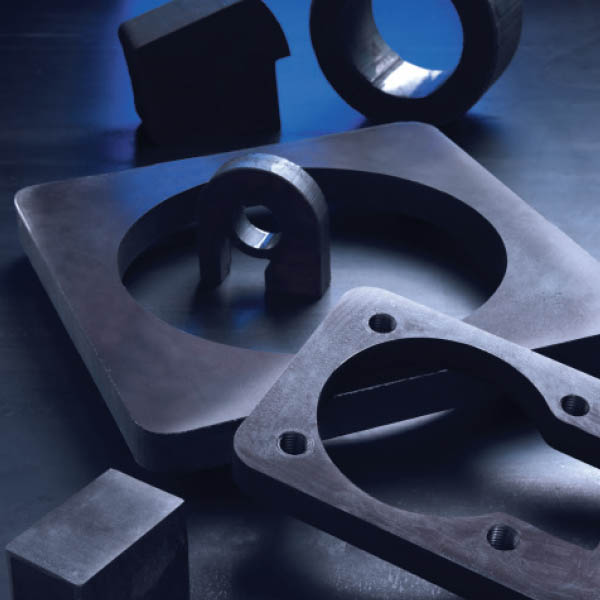

MATERIAL TYPES:

MAXIMUM THICKNESS FOR PLASMA AND OXYFUEL PROCESSING:

- Carbon steels: Oxyfuel through 6", Plasma through 1"

- Stainless steels: Plasma through 2"

TOLERANCES:

- Plasma: +/- 1/16"

- Oxyfuel:

- +/- 1/16" for material under 2" thick

- +/- 3/32" for material 2" thick and above